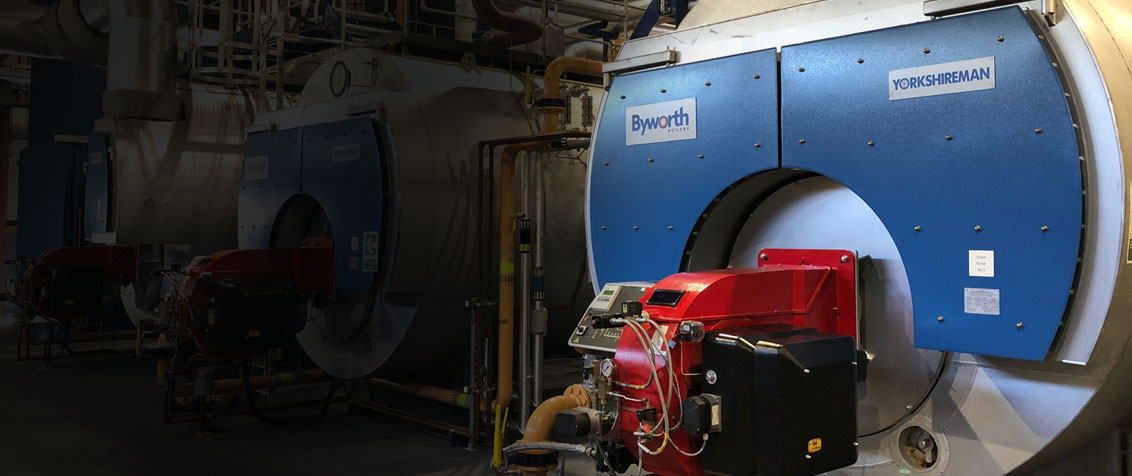

Award-winning Energy-efficient Industrial Steam Boilers and Industrial Hot Water Boilers

Maximise your industrial site efficiency

Your industrial boiler is essential to your operations and business. That’s why you need an advanced system, built to last.

With over 50 years of boiler manufacturing experience, our advanced boiler house technology helps minimise downtime, reduce fuel usage and increase operational efficiency.

Supporting both you and your system

Each icon of the lifecycle represents a team within Byworth, each able to leverage the expertise of other teams to provide the best product and services to you.

Design

We are proud to have the very best team of people working hard to ensure your boiler project runs smoothly from initial design through to completed boiler. All boilers are designed by one of our expert Design Engineers, who will work collectively with your Project Engineer and your team to ensure the boiler meets your exact design requirements.

Manufacturing

The manufacturing process at Byworth is built on a combination of over 50 years of industry experience passed down through the generations, and continued investment in our team and their equipment.

Installation

Our full range of boiler installation services are designed to support your individual site requirements.

Service

As boiler manufacturers, we know the importance of regular boiler services to maintain the energy efficiency of your boiler.

We have the expertise to offer excellent customer service for all industrial boiler services and maintenance requirements.

Training

Leverage Byworth’s market leading training facilities alongside the extensive experience of our trainers to give your operators the best opportunity to learn.

Spares

Whether you have steam boilers, industrial hot water boilers or ancillary equipment, we can provide industrial boiler supplies to fit your requirements

Explore each stage of our Lifecycle and read more about how we can help you.

Experts in our field

Your operations deserve to be powered by the very best throughout the entire lifecycle of your product. From manufacturing and installation to ongoing servicing and training, our team is on hand to help.

As industrial boiler specialists our engineers are the very best option for boiler repairs and maintenance. With three service divisions including Planned Maintenance, Break Fix, and Upgrade & Repairs, you can guarantee we have the right engineer for the job.

Solutions that fit your needs

Investing in a new industrial boiler from Byworth could offer the ideal solution to your problems.

Learn how we have already improved processes for customers like you.

“We’ve seen significant energy savings since the installing the new Byworth boiler. We think it’s about 13% less gas to brew the same amount of beer which not only a significant saving but subsequently reduces the company’s carbon footprint.”

Andrew Leman, Timothy Taylor’s Head Brewer

Not sure which boiler is right for you?

Call us on +44 (0)1535 665225 and we will advise you on the best product for your needs.