Our Story

Where it began

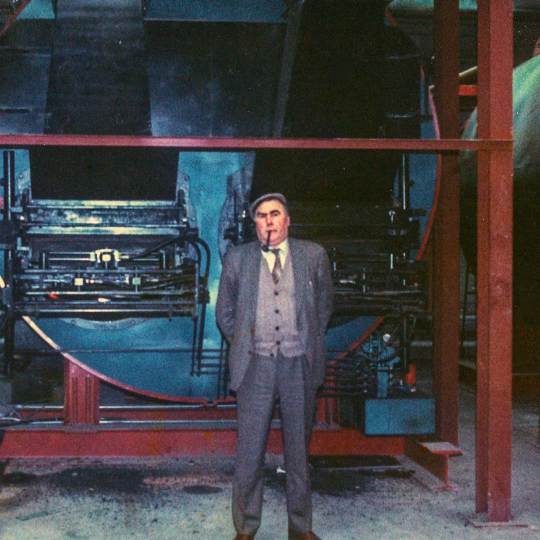

Our founder, Dennis Baldwin was a well-established chrysanthemum and tomato grower who successfully ran his own business from the young age of 17.

Based on 3 sites around Yorkshire, Dennis used steam boilers to heat his 3 acres of glasshouses, but he wasn’t happy with the standard of steam boilers available. He wanted better quality boilers with better efficiency. With an inherent talent for engineering, Dennis decided to design and install his own boiler system.

Soon after, other horticultural businesses were recognising his flair for producing high-quality steam boilers and the demand for Dennis’ innovative products began to rise.

With two sons more interested in engineering than growing, Dennis took the brave decision at age 42 to make a career change. He sold his successful horticultural company to finance a land investment to set up a factory.

This was when Dennis Baldwin & Sons Boiler Manufacturers was first established; later to be known as Byworth Boilers. Over the years the Byworth brand grew and with it, so did the site, the facilities, and the dedicated workforce.

Early growth

After just two years in business, the company erected a portal frame building and purchased a mobile cabin to use as an office.

In 1972, the company purchased their first new Bedford Arctic and low loader trailer and erected a new 5-tonne overhead crane in the yard. Remarkably, the foundations for the crane tracks were dug by hand.

In 1973 Byworth began producing boiler shells after purchasing a 2-pass dry back boiler design from long established company, Coltman’s.

1974 saw the company buying their first semi-auto sub arc welding and ex-shipyard 12” rollers. They extended the workshop again and installed a 10-tonne crane among other machinery. The workforce was extended with several platers and coded welders.

In 1975, they fabricated and erected the first half of their boiler shop, but due to a period of political unrest in the UK, clients were cancelling their orders and Byworth Boilers were close to shutting down.

Finally, work began to pick up again in 1976 and the family business was back to their familiar ways of investing – with a new roof for the boiler shop and a 20-tonne crane.

A further extension was added to the fitting shop in 1979, and a second 10-tonne crane added to the organisation's assets.

Continued investments and continuing to grow

The beginning of the 80s saw Byworth’s first 3 pass wetback steam boilers designed and produced. All of which were coal-fired.

New equipment had been purchased and installed for producing the coal stokers and increasingly, more steam boilers were being exported.

In 1982 Byworth acquired an extra 1-acre plot of land for further expansion. In ‘83 the third extension to the fitting shop was completed.

From 1984-85 Byworth purchased their first new plate rollers, allowing them to produce high-pressure boilers; along with a new 50-tonne capacity overhead crane and 2 more submerged arc welding machines with rotators and turntables.

By 1986, Byworth’s export markets included Egypt, China, Sri Lanka, Cyprus and Ireland, to name a few. The boiler range was continuing to expand due to a shift in market trend from coal-fired to oil and gas-fired boilers.

During 1987, they fabricated and erected a 150-foot extension to the boilershop to create extra floor space required for handling larger boilers.

Transforming the service offering

In 1988, Peter had attended a site where its steam boiler had experienced an unexpected breakdown. This was where he had a sudden moment of inspiration. – Why couldn’t a boiler business offer their customers an immediate service whereby they could hire boilers? And that began the concept of installing a fully packaged boiler-house into an articulated trailer, complete with fuel tank and all other ancillaries – all ready to be mobilised and to be offered out to customers on a hire basis.

Now, if a customer had a sudden breakdown or required extra production capacity, there was a solution for their problem.

Later that year, the first ever mobile steam boiler was built and hired out to a Timber merchant. Byworth Boilers’ success had grown to establish a subsidiary company – known as Byworth Transportable Boiler Hire. Within two years, the hire fleet had increased to an extended 10 boiler range.

Meanwhile, production at Byworth Boilers hit a staggering 100 boilers for the very first time.

The nineties

In 1991, the company was awarded the prestigious Royal Albert Hall contract for 4 new steam boilers.

A couple of years later, in 1993, Dennis Baldwin retired, and Peter took over as Managing Director.

Between 1995 and 1996, Thwaites yard was purchased, a result of the continuous expansion of the Hire fleet and extended range of new steam boilers.

A service division was established in the late 90’s with the new Hire Boiler service building erected in 1999.

Research and Development

Unfortunately, 2002 marked a very sad event in Byworth’s history. Dennis Baldwin sadly passed away at aged 76.

In the early 2000’s, looking to increase production by 50%, Byworth invested and erected a fitting shop at their Thwaites yard.

In 2003, Byworth purchased and installed their first CNC Plasma, installed a CNC drill and upgraded their plant rollers.

Peter’s son, Rob Baldwin, joined the company, aged 18, as an apprentice boilermaker.

Ground-breaking efficiency enhancements

During 2004, Byworth embarked on a very important venture with Leeds University. The partnership, which spanned over 2 years, was focused on improving the efficiency of shell boilers.

With a view to reduce the consumption of fossil fuels, Byworth’s Research and Development Engineer Ian Roberts, devised a program to investigate the performance of shell and tube boilers, with the objective of improving steam boiler efficiency, therefore, reducing fuel consumption.

In 2007, Dr Ian Roberts was awarded the Derek Ezra Prize by the Combustion Engineering Association for his research and development work on behalf of Byworth Boilers.

Last Decade

In 2010, Byworth employed Rob Baldwin as Production Director. The company remained under the control of the Board which comprised of the Baldwin family.

Byworth has always pushed to be at the forefront of technology. So, after almost 50 year in the manufacturing industry, we turned our attention to look at improvements that could be made in boiler-house control and management to support our new and existing customers.

The latest innovative equipment, Unity, is Byworth’s revolutionary boiler control system, which harnesses the power of digital technology to transform the industrial boiler industry. Unity began development in Spring 2013 and by Autumn 2013, the first system had been sold. A testament to its unique value, Unity won a Queen’s Award for Enterprise in Innovation in 2016.

In 2016, Gavin Hindle joined the Board of Directors as Projects Director, Gavin had also worked for the company prior to his Directorship.

In 2017, plans were passed to double the size of the boiler shop and add another 50-tonne crane. A decision that was driven by the need for extra capacity due to increased product demand.

The latest developments

The latest extension to the Byworth site was completed early 2021 and added another 135 metres to the facility. The extension included a new Customer Centre and training facilities, as well as improved breakout space for the staff.

The newly extended Byworth site is one of the only places in the UK where you can witness the full cycle of industrial boiler manufacture, from flat plate to completed boiler, all under one roof.

Following the Coronavirus pandemic, Byworth were finally able to celebrate the completion of the extension with a factory launch event in October 2021. The event gave Byworth the opportunity to show customers and suppliers round the facility, meet the team, and celebrate the companies’ achievements.

Our Values

Dennis was able to build a product that better suited the needs of the industry. These values remain today as Byworth seek to produce solutions to fit customer requirements, never offering a ‘one size fits all approach’.

Today we supply a diverse range of customers, big and small, from a multitude of industries.