We were absolutely thrilled to welcome the Prime Minister to our facility. What a fantastic opportunity for us to show the PM the innovative work we're doing, the dedication of our team, and our commitment to making a positive impact in British manufacturing.

News and Blog

All the latest news and blogs from the UK’s leading industrial boiler manufacturer

Hops, Crafts, and Good Times! BeerX 2024 and Beyond

Our low down on BeerX 2024 and the significant role it plays in supporting the craft brewing industry in the UK.

The low down on what we've been doing to promote NAW2024

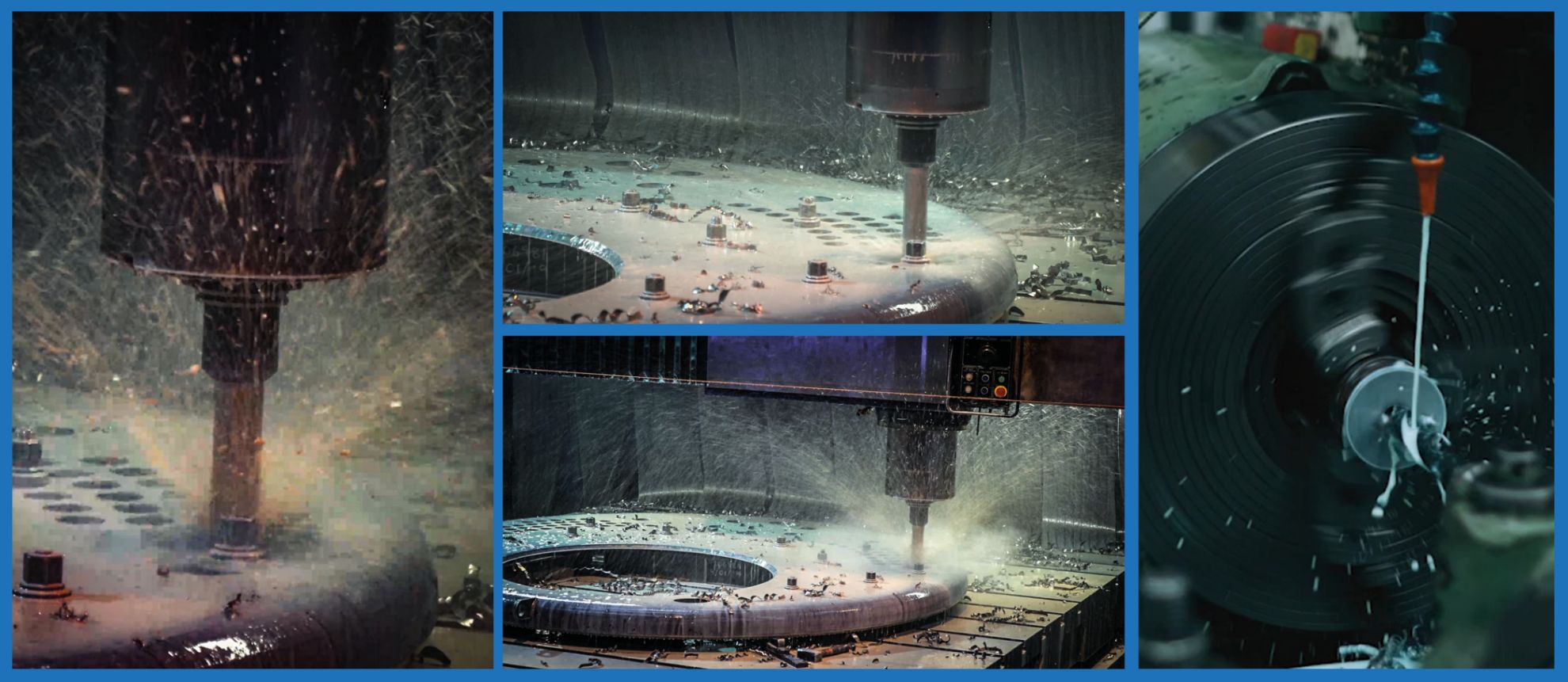

The importance of metal working fluid in our industry and the safety measures that go with it

How welding apprentice Harry has gone from strength to strength in 2023

Our journey to a three trainer strong team delivering and developing multiple courses, in state of the art facilities.

Why you need help to regularly service your industrial boiler

Some of our team have been working hard on their personal development by taking part in Jamie Peacock's Building Champions program

In this blog we will discuss the safety procedures and plans put in place at Byworth Boilers for MEWP operators, all of which comply with the Health and Safety legislative requirements, and the Working at Height Regulations 2005.

Byworth's first trade show in four years did not disappoint

- 1

- 2

.jpeg)

.jpeg)

.jpeg)