A follow on piece that focuses on continuous improvement, clearer communication, and delivering exceptional value to our customers.

News and Blog

All the latest news and blogs from the UK’s leading industrial boiler manufacturer

Celebrating International Women in Engineering Day

Our latest blog explains why you don’t need to be an engineer to be part of engineering

Here's why regular burner servicing is so vital—and how often you should be doing it.

IWD is not just about posting a picture of the women within our organisations it’s about showcasing how they are making a difference and how this translates to future generations.

A quick Q&A session with three individuals to explore the contributions they’ve made and how their expertise is driving positive change within Byworth Boilers.

At the end of 2024, our newest recruits were the latest team members to successfully attend and complete their IPAF Training to safely use and operate mobile elevating work platforms (MEWPs). Road more to learn why this is important for the safety of our site and team.

A full round up of all the achievements and successes from the Byworth Team in 2024

This article shares our top tips for preparing your boiler for winter, ensuring it remains efficient when in use.

What is Bradford Manufacturing Week and why is it important for the continued growth of our industry.

Use it or lose it. Why we should be buying British

Understanding the causes and consequences of dangerous low water. Click here to read more and learn how you can avoid dangerous low water.

Industrial boilers are at the heart of many manufacturing processes, but what fuel is the best for powering your boiler?

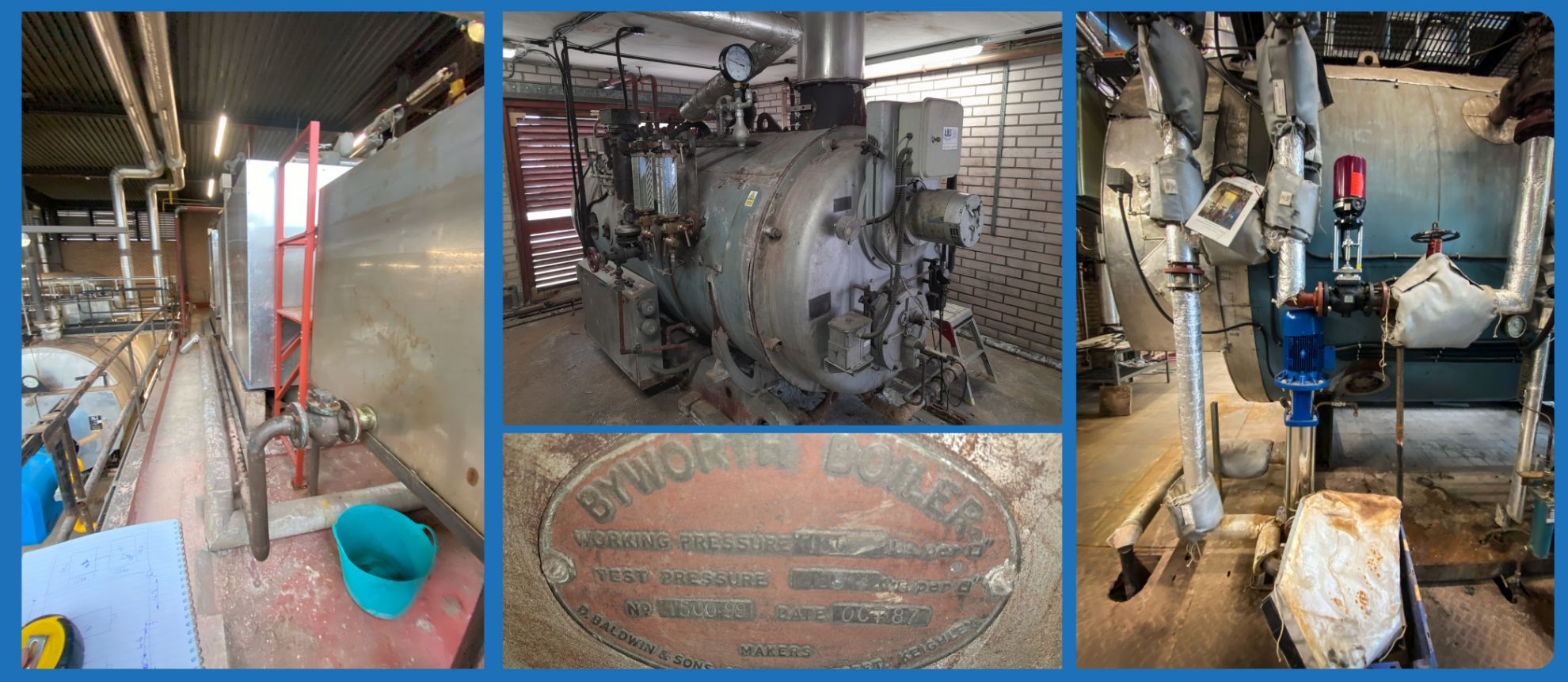

The many factors that will determine the lifespan of your industrial boiler.

How to ensure the future of your business is brighter, greener, more efficient, and more economically sustainable than ever before.

Our low down on BeerX 2024 and the significant role it plays in supporting the craft brewing industry in the UK.

We were absolutely thrilled to welcome the Prime Minister to our facility. What a fantastic opportunity for us to show the PM the innovative work we're doing, the dedication of our team, and our commitment to making a positive impact in British manufacturing.

The low down on what we've been doing to promote NAW2024

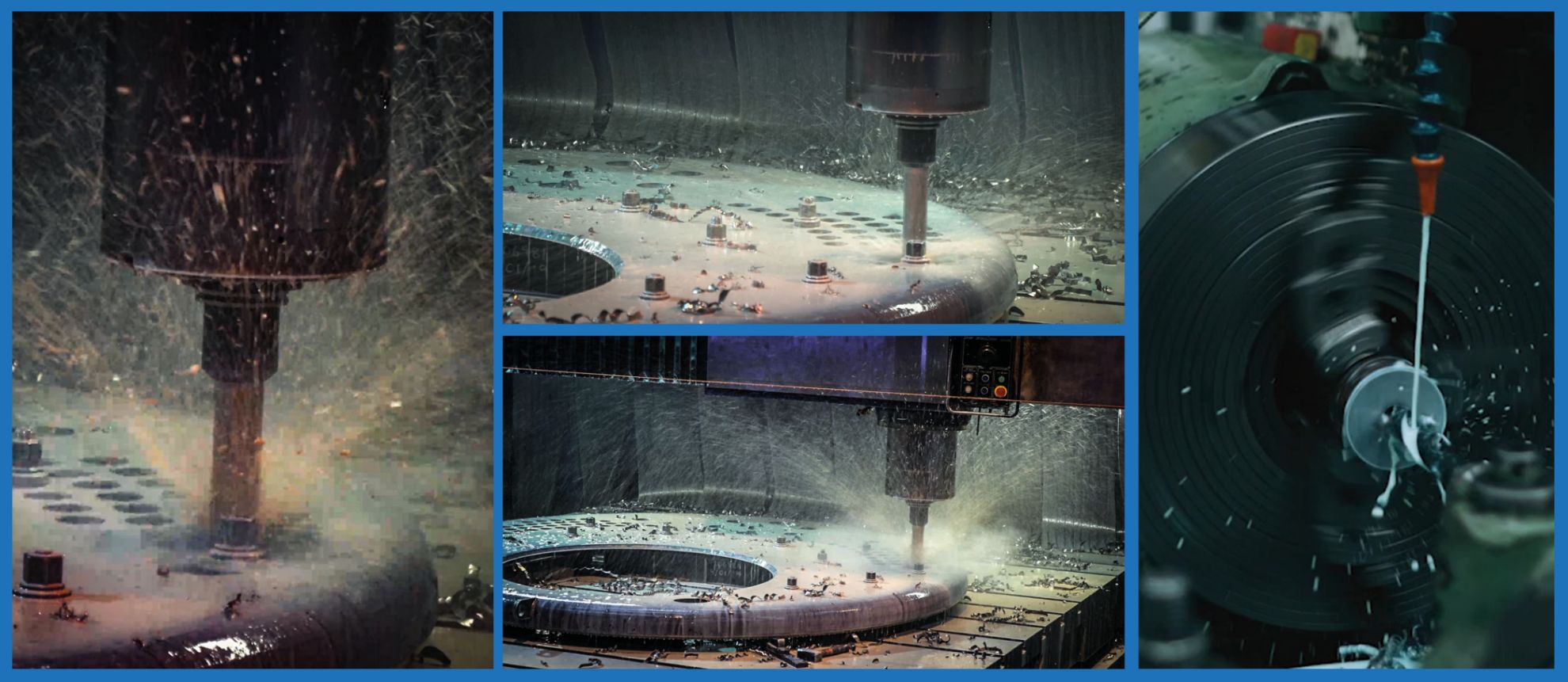

The importance of metal working fluid in our industry and the safety measures that go with it

How welding apprentice Harry has gone from strength to strength in 2023

Our journey to a three trainer strong team delivering and developing multiple courses, in state of the art facilities.

Why you need help to regularly service your industrial boiler

Some of our team have been working hard on their personal development by taking part in Jamie Peacock's Building Champions program

- 1

- 2

.jpeg)

.jpeg)